4 Steps for Waterproofing Pools

Swimming pool leaks are frustrating – and addressing them is often expensive, time-consuming, and sometimes requires removing tile and adhesives. To help your clients enjoy their pools without interruption, consider using a waterproofing and crack isolation membrane.

Selecting a Waterproofing Method:

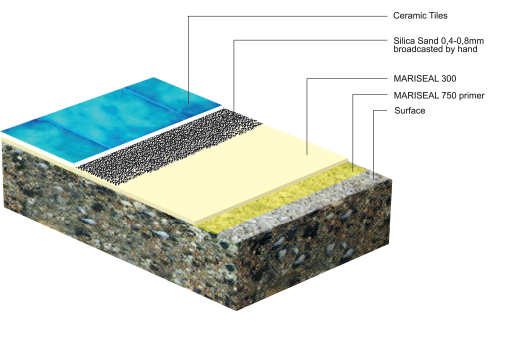

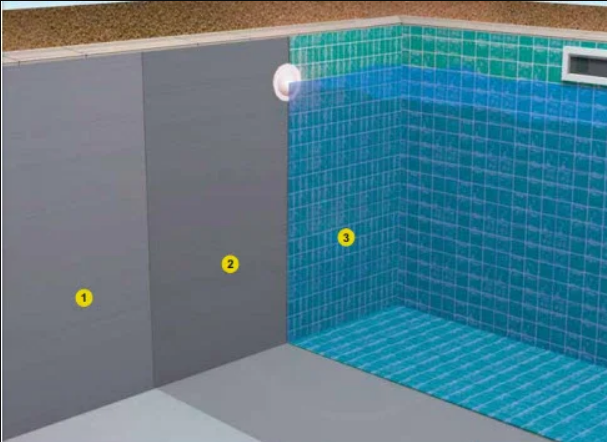

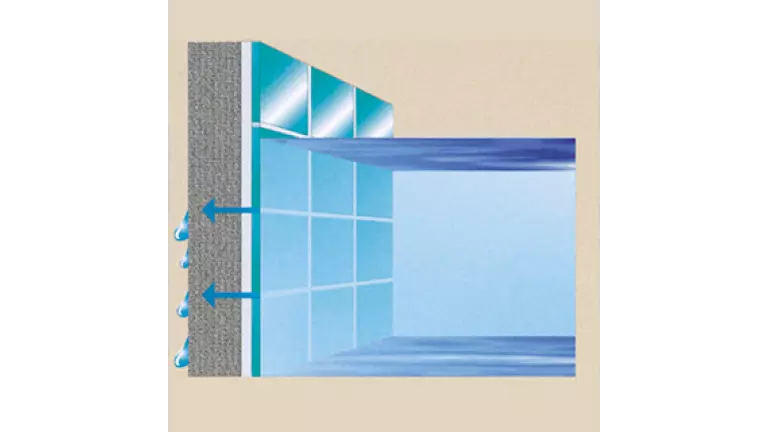

Tile pools, as described in P602 of the TCNA handbook, require a cementitious waterproofing product over their concrete shells. These products address both negative hydrostatic pressure, which is water pressure that comes from beneath or behind the pool’s substrate, and positive hydrostatic pressure, which is pressure placed on the substrate from above, by the water in the pool.

You can additionally address positive hydrostatic pressure with a waterproofing and crack isolation membrane, which can help prevent water from leaking into the mortar bed. This membrane helps prevent problems associated with saturation and moisture expansion and is applied to the substrate’s surface and allowed to cure before tiling begins. Its crack isolation properties are particularly important in freeze/thaw environments. Look for a membrane that allows for the direct bonding of tile for an efficient installation.

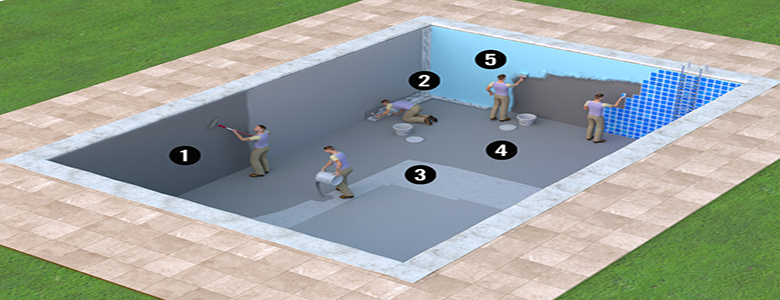

1. Smooth the Substrate

You need to bring any variations in the pool’s wall or floor (the mortar bed bonded to the cementitious waterproofing), within acceptable flatness levels. TEC® Fast-Set Deep Patch mixed with XtraFlex™ can be used effectively in this application for swimming pools.

2. Clean the Substrate

To facilitate a strong bond for your waterproofing membrane and the tile, ensure that the substrate is properly prepared. Proper preparation requires removing any contaminants on the substrate’s surface – including grease, residues and dust; as well as all loose materials, such as those resulting from honeycombing or laitance. Possible methods for cleaning include pressure washing, scarifying, sandblasting, shot blasting and grinding. After final preparation, remove all dust by vacuuming, clean the surface with a wet sponge and let it dry before applying the membrane. If the concrete has no contamination, you may only need to scrub and wash it.

3. Apply the Waterproofing Membrane

Apply the waterproofing membrane of your choice as per the manufacturer’s instructions. TEC® HydraFlex™ Waterproofing Crack Isolation Membrane can be applied by roller, trowel or spray over concrete as new as three days old and cures in just two to three hours. Prior to coating the entire surface with the membrane, pre-fill all concrete cracks up to 1/8” wide. Flash all control joints, substrate joints, field seams and corners; anywhere vertical surfaces meet horizontal surfaces, such as curbs, bench seats and columns; anywhere dissimilar materials meet, such as drains and expansion/control joints. All flashing should be done per the product instructions using Waterproofing Mesh.

Once flashing is complete, apply the membrane to the entire surface using a 1/4” to 1/2” nap roller, 3/16” v-notch trowel or airless sprayer. Apply one coat in a minimum thickness of 25 mils wet. Allow this coat to dry for 1 hour, or until the membrane becomes semi-transparent, and then apply a second coat 25 mils wet, at a right angle to the first coat.

4. Test for Leaks

Once the membrane is properly cured, test to make sure the pool is watertight before beginning the tile installation. To do so, fill the pool at a slow rate. For comparison, fill a test vessel with water and keep it next to the pool. Measure the water levels of both the pool and test vessel after filling, and again after several days. If the pool and test vessel have lost similar amounts of water, evaporation or wind are probably the culprit. However, if the pool has lost significantly more water than the test vessel, you will need to drain the pool and make repairs to the waterproofing system.

Your pool pump is kind of like the “heart” of your swimming pool. The pump draws water through the filtration system, where it’s stripped of dirt, debris, and other impurities. From there, the clean water goes back to the pool.

Phase testing can help you isolate the source of any leaks. Fill the pool partially – below any fixtures in the wall – and conduct testing. If no leaks are detected, fill the pool above the first level of fixtures and repeat testing. Again, if there is no evidence of a leak, fill the pool and conduct a final test. If a leak is detected at any stage, drain the pool as much as necessary to conduct repairs. Your customers are probably eager to get their pool up and running. But don’t let that encourage you to skip steps in the waterproofing process. Properly waterproofing a pool – and checking its effectiveness – helps ensure that your clients will be able to enjoy their pool all season.

Pressure Grouting

Pressure Grouting is the process of pumping a cement or chemical grout into soft or weak strata of soil or voids. This grout fills these voids, thus stabilizing and strengthening the soil. Pressure Grouting has many applications. One of these includes support for existing structures or where foundations have shifted.

1. he purpose of Pressure Grouting is to control the amount of grout going into the pipe. As the process is repeated at additional elevations, the soil is compacted.

2. The process begins with the pumping of grout at the lowest elevation. The pipes are withdrawn slightly and the grout is allowed to set.

3. The process is repeated at the next elevation. Upon completion, the pipe is again withdrawn slightly to the next elevation. The grout is allowed to set. Each level of grout pumping will push the soil upward.

4. The number of grout pumpings at these different elevations that are needed to compact the soil will vary. Once the soil is compacted, it causes lift. This lift then pushes the footing and wall upward.